In the era of the digital revolution, the plastics industry is undergoing a fundamental transformation that goes beyond traditional production methods and opens the door to new technological horizons. The Plastics Cluster is at the forefront of this evolution, integrating breakthrough technologies that increase the efficiency, productivity and innovation potential of the industry.

Digitalisation in production

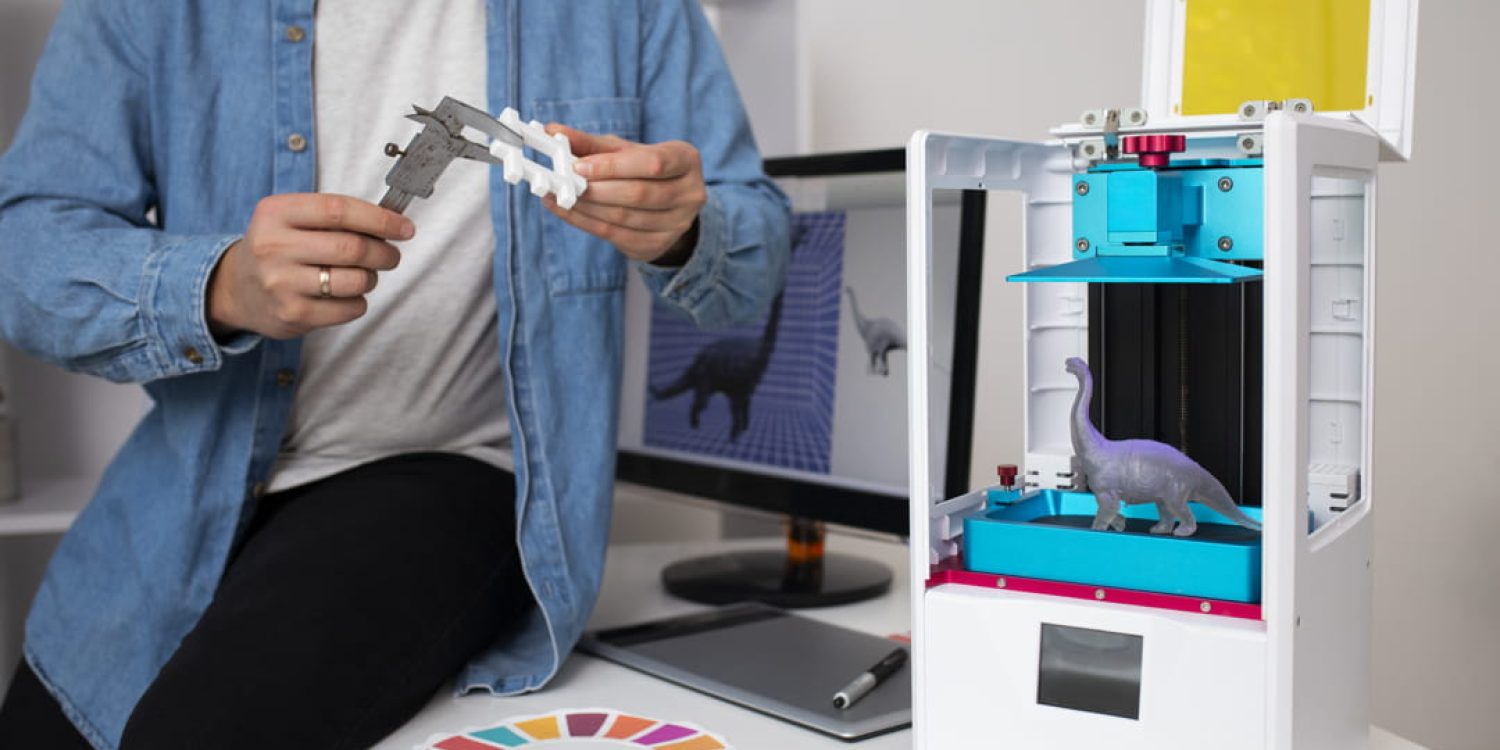

Digitalization and automation have become key words in the modern plastics industry. From advanced robotic processing, to 3D printing, to the implementation of artificial intelligence to optimize manufacturing processes, these technologies are enabling plastics manufacturers to achieve exceptional levels of precision, flexibility and sustainability.

- Robotic Processing: Robotics offers unprecedented levels of automation and efficiency, minimizing human error and increasing productivity.

- 3D Printing.

- Artificial Intelligence: The application of AI in manufacturing processes brings the ability to predict maintenance, optimize production and personalize products based on data.

Adapting to a new era

The introduction of these technologies also brings challenges such as the need for skilled workers and securing investment. The Plastics Cluster is actively working to overcome these barriers through training programmes, collaboration with technology partners and support from government and international funds.

Sculpture in the digital era

The digital transformation of the plastics industry is not just a future aspiration; it is a reality that is happening now. The Plastics Cluster is at the forefront of this revolution, pushing the boundaries of what is possible in plastics manufacturing and showing the way to a prosperous, efficient and technologically advanced future.